Delta Unveils AI Cobots, Digital Twins to Revolutionize India's Manufacturing

Delta's AI cobots and digital twins pioneer smart manufacturing, propelling India toward semiconductor self-reliance.

September 3, 2025

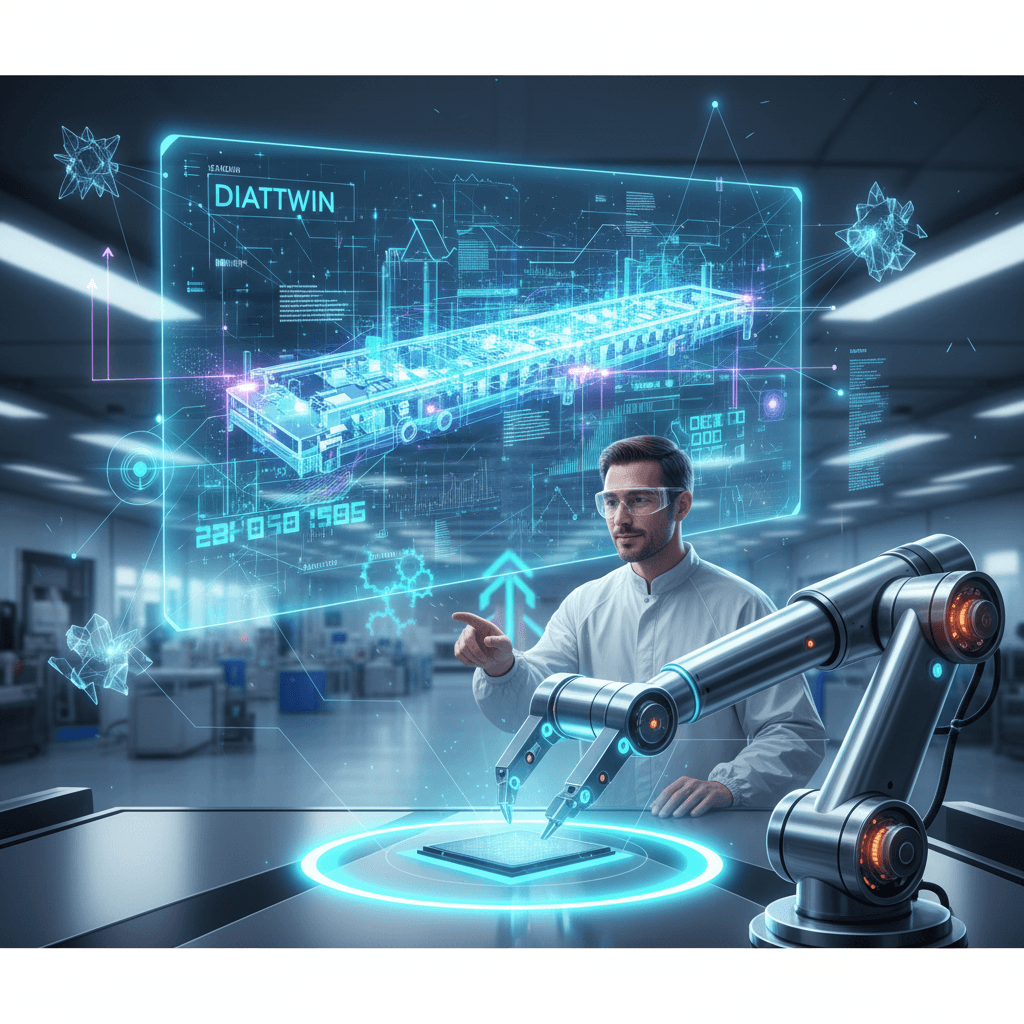

Amidst a major push for technological self-reliance, Delta Electronics has seized the spotlight at SEMICON India 2025, unveiling a suite of next-generation smart manufacturing solutions poised to accelerate the nation's burgeoning semiconductor and electronics industries. The company presented its advanced D-Bot series of collaborative robots (cobots) and the sophisticated DIATwin digital twin platform, signaling a significant leap in integrating artificial intelligence and virtual simulation into the factory floor. These innovations arrive at a crucial moment, aligning directly with the Indian government's "Make in India" and India Semiconductor Mission initiatives, providing critical tools for the high-precision, high-stakes world of electronics manufacturing. Delta's showcase is not merely a product launch but a statement of intent to become a foundational partner in building India's high-tech industrial ecosystem, offering solutions that promise to enhance efficiency, safety, and intelligence in production environments.

The centerpiece of Delta's automation showcase is its D-Bot series of collaborative robots, a family of machines designed to work safely and efficiently alongside human employees. With payload capacities ranging from a nimble six kilograms to a robust 30 kilograms and reach spans extending up to 1800 mm, these cobots are engineered for versatility, capable of handling delicate pick-and-place operations as well as more demanding tasks like welding and palletizing.[1][2] What sets them apart is their deep integration of AI and advanced safety protocols. A key feature is the "Reflex Safety" function, which ensures the robot halts or reverses its movement instantly upon contact with an object or person, enabling cage-free operation and fostering a truly collaborative workspace.[3][4][2] Further enhancing this human-robot synergy is an available AI Cognitive Module kit, which facilitates intuitive interaction through speech, gestures, and 3D object recognition, making the robots more accessible to operators without specialized programming skills.[2] Designed for the rigors of industrial settings, the D-Bot series boasts an IP66 rating for protection against dust and water, ensuring reliability and minimal maintenance in demanding manufacturing environments.[3][1][4]

Beyond physical automation, Delta is revolutionizing the design and deployment of manufacturing processes with its DIATwin Virtual Machine Development Platform. This powerful digital twin technology allows engineers and manufacturers to create high-fidelity, physically accurate virtual replicas of machines and entire production lines before a single piece of hardware is assembled.[5][6][7] By leveraging this virtual environment, companies can simulate, verify, and commission equipment offline, drastically reducing the costly and time-consuming trial-and-error phase of setting up new production lines.[8] The platform's impact is substantial, with demonstrated ability to shorten new product introduction timelines by approximately 20% and, in specific applications like optimizing the glue dispensing paths of robotic arms, cutting machine commissioning time by over 80%.[9][7] This virtual-first approach is particularly vital in the semiconductor industry, where precision is paramount. For instance, DIATwin can be used to model and optimize wafer handling parameters in a simulation, enhancing accuracy and reducing potential downtime before changes are ever applied to live equipment.[5][7] The platform integrates advanced AI and can utilize powerful simulation engines like NVIDIA Omniverse, enabling the generation of synthetic data to train computer models to achieve up to 90% accuracy.[9][10]

The strategic importance of these technologies for India's national ambitions cannot be overstated. As India works to establish itself as a global semiconductor hub, the availability of locally supported, cutting-edge manufacturing technology is a critical success factor.[11][12] The high capital investment and microscopic tolerances required in chip fabrication demand solutions that minimize risk and maximize yield. Delta’s digital twin platform directly addresses this need by allowing for extensive virtual prototyping and process optimization, while its high-precision cobots provide the reliable automation necessary for sensitive assembly tasks. Benjamin Lin, President of Delta Electronics India, has emphasized the company's alignment with the government's vision, highlighting a commitment to localized innovation and empowering manufacturers with reliable, secure, and intelligent solutions.[2] By providing the foundational tools for smart manufacturing, Delta is positioning itself not just as a supplier but as a crucial enabler of the entire ecosystem, supporting the complex production lines and facilities that will define India's semiconductor future.[13][14] This contribution is vital for building the resilient and competitive high-tech manufacturing landscape envisioned by the India Semiconductor Mission.

In conclusion, Delta Electronics' showcase at SEMICON India 2025 marks a pivotal moment in the evolution of smart manufacturing in the region. The unveiling of AI-integrated cobots that can safely and intuitively work with humans, alongside a digital twin platform that perfects processes in the virtual world before they exist in the physical, represents a profound shift in industrial capability. These advancements are far more than incremental improvements; they are transformative tools that offer the precision, efficiency, and resilience required by the next generation of high-tech industries. For the AI sector, this represents the tangible application of intelligent systems at the very core of production, moving from data analysis to direct physical and procedural influence. As India continues its ambitious journey to become a semiconductor powerhouse, the sophisticated automation and virtualization technologies pioneered by companies like Delta will be instrumental in laying a robust foundation for innovation, productivity, and sustained growth in the global market.