AI Empowers Spot Robot to Detect and Prevent Industrial Hazards

Now an AI-powered watchdog, Boston Dynamics' Spot actively identifies hazards, fundamentally transforming industrial safety from reactive to proactive.

June 24, 2025

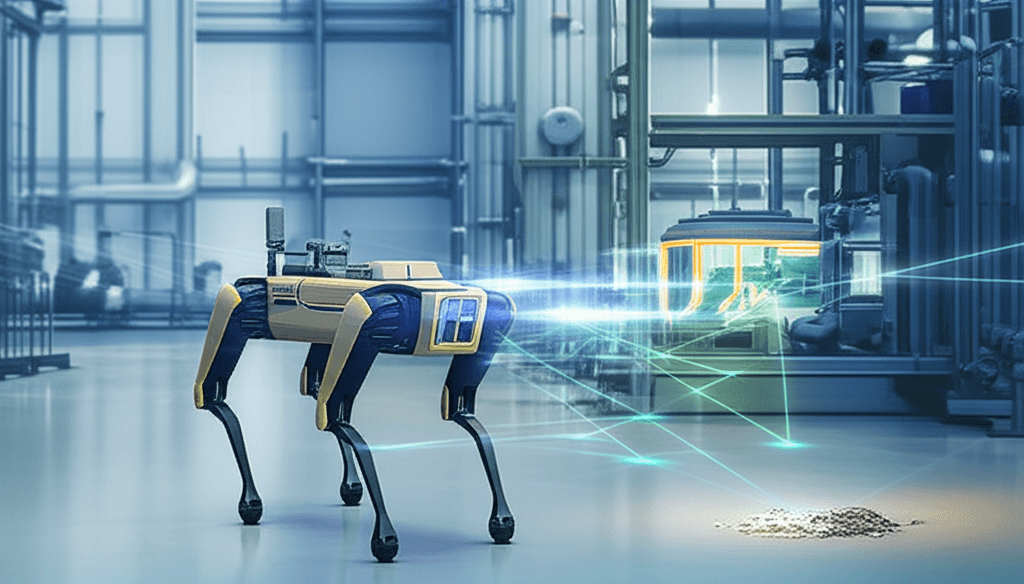

The familiar four-legged form of Boston Dynamics' Spot robot, a machine that has captured public imagination through viral videos of its nimble movements, is becoming an increasingly common sight in industrial environments, taking on tasks that are dangerous, dull, or difficult for its human counterparts.[1][2] Now, with an updated system powered by artificial intelligence, Spot's role as a safety watchdog is expanding, allowing it to identify and flag a growing list of potential hazards, from misplaced equipment to spills on a factory floor. This evolution marks a significant step in the application of advanced robotics and AI to create safer and more efficient industrial operations.[3][4]

At the core of Spot's enhanced safety inspection capabilities is an AI-powered visual analysis system integrated into its software.[3] This system allows the robot to not only navigate complex and unstructured environments but also to interpret what it "sees" through its cameras.[5] For instance, in a recent application at a Cargill multiseed processing plant, Spot has been tasked with identifying risks like seed spills, which can create slip and trip hazards for employees.[3] The robot autonomously patrols the facility, particularly during second and third shifts and on weekends to avoid peak human traffic, and uses its vision system to detect these spills.[3][6] When a hazard is identified, the system can alert human managers who can then dispatch a team to address the issue, preventing potential accidents before they occur. This proactive approach to safety is a fundamental shift from traditional reactive measures.

The system's capabilities extend far beyond simple spill detection. Through a combination of its own technology and partnerships with companies like Levatas, an AI software provider, Spot can be equipped to recognize a variety of safety and compliance issues.[7][8] These can include identifying ajar emergency exits, ensuring fire safety equipment is unobstructed, and detecting unauthorized personnel in restricted areas.[3][7] The robot's payload is highly customizable, allowing for the integration of various sensors to meet specific industrial needs.[9][10] For example, thermal cameras can be mounted to detect overheating machinery, a critical function in preventing equipment failure and potential fires.[9][3] In one instance at the Cargill plant, thermal scans from Spot identified a ventilation problem with bearings that were fluctuating between 40 and 100 degrees Celsius, an issue that could have led to a system jam if left undetected.[3] Similarly, acoustic imagers can "listen" for and visualize air leaks in compressed air systems, a common source of energy waste and potential failure points.[9][1]

The implications of this technology for the broader AI and industrial sectors are profound. By automating routine inspection tasks, companies can gather vast amounts of consistent and reliable data that was previously difficult or impossible to obtain.[4] This data is crucial for powering predictive maintenance programs, allowing companies to move from a reactive "fix-it-when-it-breaks" model to a proactive one where potential failures are identified and addressed before they lead to costly downtime.[5][6] The consistent data collection performed by Spot, always from the same angle and distance, provides a reliable historical record that can be used to track trends and identify subtle changes over time.[6] This data-driven approach not only improves operational efficiency but also significantly enhances worker safety by removing humans from potentially hazardous environments and tasks.[11][12] Companies like Hyundai have begun pilot programs using Spot for late-night security patrols and safety checks in their manufacturing plants, underscoring the growing confidence in this technology.[13][14] The robot's ability to navigate challenging terrains, from cluttered factory floors to the uneven ground of construction sites and even agricultural fields, makes it a versatile tool for a wide range of industries.[12][15][16][17]

In conclusion, the integration of advanced AI into Boston Dynamics' Spot robot represents a significant leap forward in workplace safety and industrial automation. The ability to autonomously identify a wide array of hazards, from the mundane, like a seed spill, to the critical, like an overheating motor, transforms the robot from a mere data collection platform into an active participant in risk mitigation. As this technology continues to develop and becomes more widely adopted, it promises to not only streamline operations and reduce costs but also to create fundamentally safer working environments across a multitude of industries. The partnership between human workers and intelligent robots like Spot is poised to redefine the future of industrial work, where data-driven insights and automated vigilance become the new standard for operational excellence and employee well-being.

Sources

[1]

[2]

[4]

[6]

[8]

[10]

[12]

[13]

[14]

[15]