AI Billions Flood Logistics, Yet Data and Culture Hinder Deployment

AI investment in logistics is booming, but a disconnect in data, skills, and strategy prevents widespread impact.

June 27, 2025

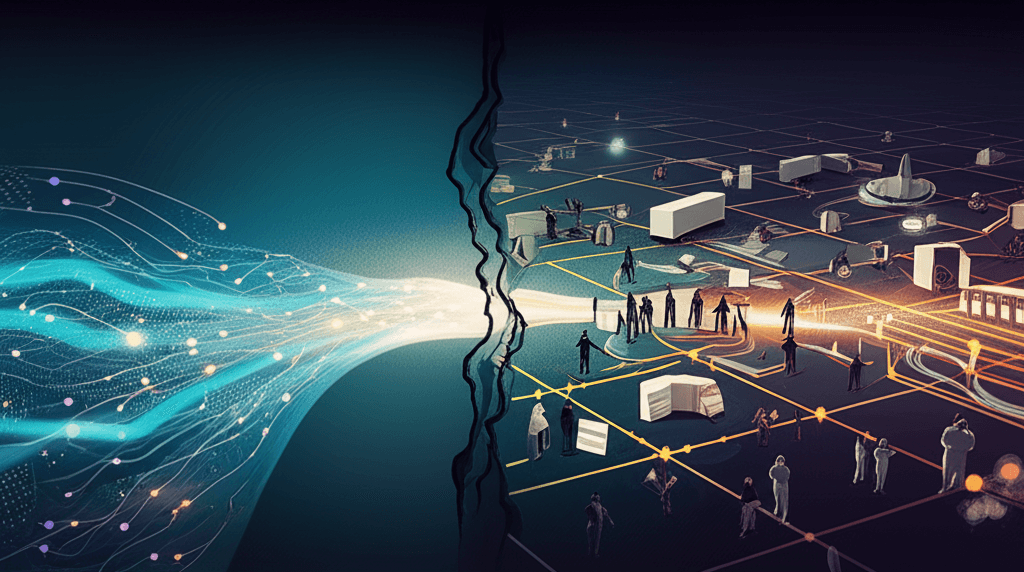

A wave of significant investment is pouring into artificial intelligence for the logistics sector, yet the real-world deployment of this transformative technology is not keeping pace with the enthusiasm. The global market for AI in logistics and supply chain has seen explosive growth, with some reports valuing it at nearly $20 billion in 2025 and projecting it to soar to over $157 billion by 2033.[1][2][3][4] This financial commitment underscores a widespread belief in AI's potential to revolutionize everything from warehouse management to last-mile delivery. However, a closer look reveals a critical disconnect between investment and successful implementation, as many companies struggle to move beyond pilot projects and integrate AI into their core operations. Despite the clear benefits, which include significant cost reductions and efficiency gains, a host of deeply entrenched challenges are preventing the logistics industry from fully capitalizing on its AI investments, demanding a more strategic approach to adoption.[5][6][7]

The primary obstacle hindering widespread AI deployment is the quality and accessibility of data. AI systems are fundamentally dependent on vast amounts of high-quality, structured data to learn and make accurate predictions.[8][9] However, the logistics industry often operates on fragmented and outdated legacy systems, resulting in data silos, inconsistencies, and incomplete information.[10][8][9] A 2024 MIT study found that the average logistics organization uses only 23% of its available data for AI applications.[1] It is common for companies to spend 60-70% of their AI project budgets on data preparation and integration alone.[1] This foundational issue of poor data quality can lead to inaccurate AI outputs, potentially causing more harm than good and undermining trust in the technology.[10] Without a concerted effort to establish robust data governance and integration frameworks, the full potential of AI remains locked away in disparate systems.[10][11]

Beyond the technical hurdles of data management, significant organizational and financial barriers persist. The upfront cost of implementing AI, including the procurement of advanced software and hardware and the customization of solutions, can be substantial, particularly for small and medium-sized enterprises.[8][9][5] This financial barrier is compounded by uncertainty surrounding the return on investment, as AI projects often require a long lead time to demonstrate measurable benefits.[9] Furthermore, there is a significant shortage of skilled professionals who possess expertise in both AI and logistics.[1][8] This talent gap makes it difficult for companies to build the necessary teams to manage and scale AI initiatives effectively.[7] Compounding this is a cultural resistance to change within a traditionally manual industry.[10][9] Employees may fear job displacement or be wary of new, unproven technologies, making change management a critical, yet often overlooked, component of successful AI adoption.[10][12] In fact, one survey indicated that 72% of failed logistics AI implementations cited workforce resistance, not technical issues, as the primary cause.[1]

To bridge the chasm between investment and effective deployment, logistics companies must adopt a more holistic and strategic approach. This begins with moving beyond isolated pilot projects to develop a clear, overarching AI strategy with well-defined objectives, whether it's reducing fuel consumption, improving demand forecasting, or enhancing customer satisfaction.[13][9] Investing in data infrastructure and governance is non-negotiable.[11] This includes cleaning existing datasets and, where possible, establishing a single source of truth to ensure the AI has access to reliable information.[10] Addressing the human element is equally crucial. Companies must invest in upskilling their existing workforce and creating training programs to bridge the skills gap.[11][14][7] Fostering a culture of innovation and clearly communicating the benefits of AI can help alleviate employee concerns and encourage adoption.[9][14] For many, partnering with specialized AI providers can offer a cost-effective and scalable way to access expertise and technology without having to build everything from scratch.[8][14] This strategic, phased approach allows companies to demonstrate tangible benefits with smaller projects, building the confidence and momentum needed for wider, more transformative implementation.[9]

In conclusion, while the financial world has enthusiastically backed the potential of AI to reshape the logistics industry, money alone is not enough to guarantee success. The path from investment to widespread, effective deployment is fraught with challenges related to data quality, legacy systems, high costs, and workforce adaptation.[8][14][5] Industry leaders who have seen success, such as Maersk and UPS, have demonstrated that a deliberate and strategic approach is required.[1] They have shown that AI can deliver remarkable improvements in efficiency, cost reduction, and service levels when implemented thoughtfully.[1][4] For the logistics sector to fully realize the transformative power of its AI investments, it must shift its focus from mere acquisition of technology to a deeper, more integrated strategy that addresses its foundational data, workforce, and cultural challenges. The companies that navigate this complex transition will not only survive but will lead the future of a smarter, more resilient global supply chain.[11][5]