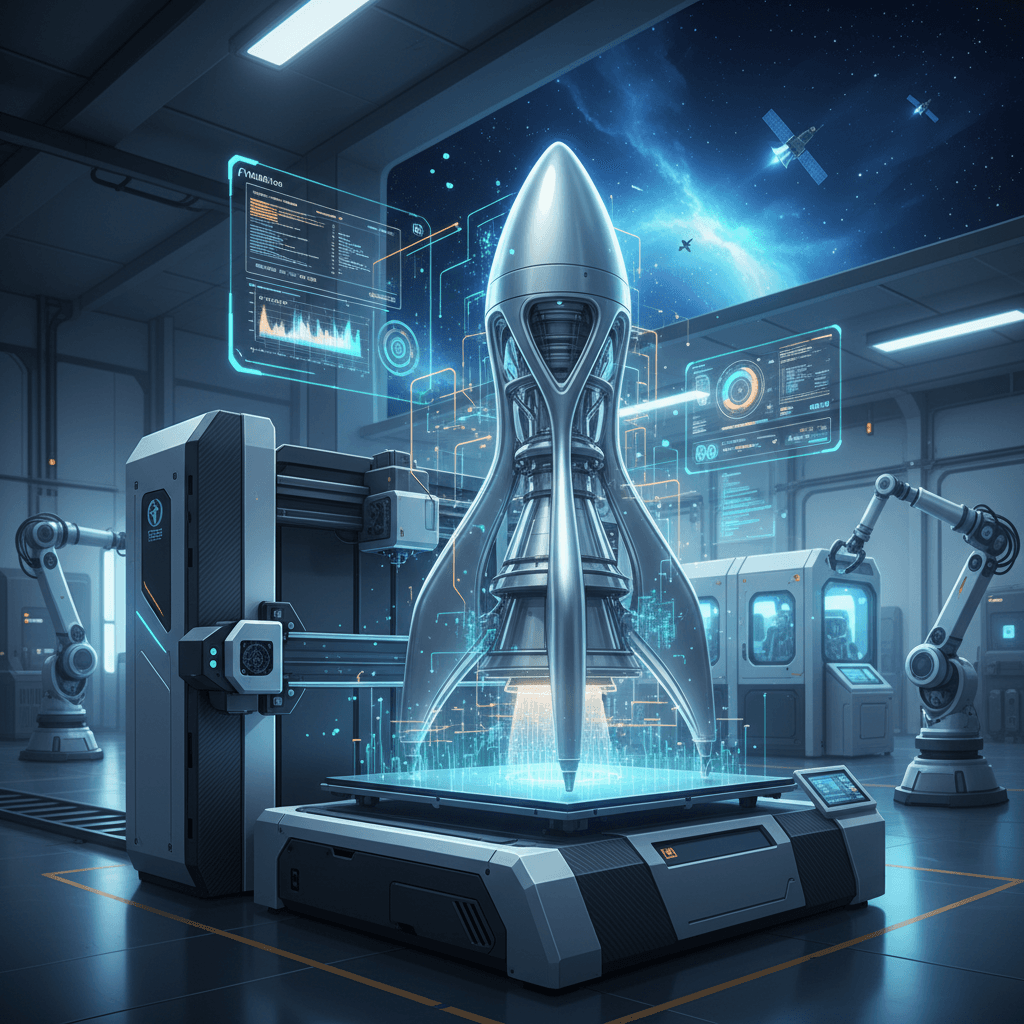

Agnikul Cosmos Commissions India's First Rocket 3D Printing Hub, Revolutionizing Production.

India's pioneering 3D printing hub, leveraging AI, slashes rocket costs and build times, democratizing space access.

September 23, 2025

In a significant leap for India's burgeoning private space industry, Chennai-based startup Agnikul Cosmos has officially commissioned the nation's first large-format rocket 3D printing hub. This state-of-the-art additive manufacturing facility, located at the IIT Madras Research Park, is poised to revolutionize how launch vehicles are built, dramatically accelerating engine production and strengthening the country's sovereign space capabilities. The hub represents a critical piece of infrastructure in the global shift towards more agile and cost-effective space access, positioning Agnikul as a key player in the competitive small satellite launch market. By bringing the entire process of rocket engine manufacturing under one roof, from design and simulation to printing and post-processing, the company is set to significantly reduce production timelines and costs, heralding a new era of rapid and on-demand space transportation.[1][2]

The core of this new facility is its advanced additive manufacturing capabilities, which enable the 3D printing of large-scale aerospace components, including entire rocket engines in a single piece.[3][4][5] For the first time in India, the facility can produce components up to one meter in height, a crucial threshold for building more powerful engines.[1][2] Agnikul claims this vertically integrated approach will slash the cost of building for space by as much as 50 percent and reduce the delivery time for flight-ready hardware from months to a matter of days.[2] This rapid iteration is made possible by eliminating the complex supply chains and prolonged lead times associated with traditional manufacturing. Instead of assembling thousands of individual components, Agnikul's patented technology allows for the creation of a monolithic engine structure, which inherently has fewer points of failure and is lighter in weight.[6][7] The facility is also equipped with an indigenously designed and developed de-powdering machine, a critical post-processing system that ensures a flawless surface finish and space-grade quality for the printed parts, reducing reliance on foreign technology.[1]

This technological advancement has profound implications for the space industry, primarily by democratizing access to space.[8] The traditional model of rocket production is notoriously slow and expensive, creating a bottleneck for the growing number of companies and research institutions needing to deploy small satellites. Agnikul’s approach directly addresses this challenge. Their flagship launch vehicle, the Agnibaan, is a highly customizable rocket capable of carrying payloads up to 100 kg to low Earth orbit.[9] The rocket's "plug-and-play" engine configuration allows it to be adapted to specific mission requirements.[9] With the new facility, Agnikul can now manufacture the seven engines required for the Agnibaan's first stage in-house and at an accelerated pace. This capability to build rockets quickly and efficiently is a game-changer for the small satellite market, which demands flexible and responsive launch services.[8] The ability to launch from multiple ports, facilitated by a mobile launchpad named "Dhanush," further enhances this flexibility.[10] This model of on-demand space access is crucial for deploying satellite constellations for communications, Earth observation, and scientific research.[8]

The convergence of additive manufacturing and artificial intelligence is a key enabler of this manufacturing revolution. While Agnikul has not detailed the specifics of its AI integration, the aerospace industry is increasingly leveraging AI in 3D printing for several critical functions. AI-driven generative design algorithms can create highly optimized and lightweight structures that would be impossible for humans to design.[11][12] These algorithms simulate thousands of design variations to find the most efficient solution for a given set of constraints, such as weight, strength, and thermal resistance.[12] Furthermore, AI plays a crucial role in process monitoring and quality control.[13] Machine learning models can analyze real-time data from sensors within the 3D printers to detect and correct anomalies during the printing process, ensuring the integrity and reliability of the final component.[13] This predictive quality control is essential in an industry where even microscopic flaws can have catastrophic consequences.[11] By employing these AI-powered techniques, manufacturers can significantly reduce material waste, improve production efficiency, and ensure that every component meets the rigorous standards of the aerospace industry.[11][14]

The establishment of Agnikul's 3D printing hub is a landmark achievement for India's private space ecosystem and a testament to the country's growing technological prowess. By pioneering the use of large-format additive manufacturing, the company is not only enhancing its own launch capabilities but also building a foundation for a more self-reliant and globally competitive Indian space industry.[15] This move aligns with the Indian government's vision of fostering private participation in the space sector, creating an environment where startups can innovate and thrive.[8] The ability to rapidly produce reliable and cost-effective rocket engines will undoubtedly attract both domestic and international customers, solidifying India's position as a significant player in the global space economy. As Agnikul scales up its production, this facility will serve as a powerful symbol of India's journey towards becoming a hub for advanced space technology manufacturing, driven by innovation, efficiency, and the ambition to make space accessible to all.