Bosch Commits €2.5 Billion to AI to Build Autonomous 'Factory of the Future'

The industrial giant deploys €2.5 billion to embed autonomous Agentic AI across manufacturing and mobility.

January 8, 2026

The gargantuan wave of data generated by modern industrial facilities has created a chasm between information and actionable intelligence, a gap that global technology giant Bosch is moving aggressively to close with a staggering financial commitment to artificial intelligence. The company has announced a plan to invest more than €2.5 billion in the application and development of AI by the end of 2027, signaling a fundamental shift in its core manufacturing and product development priorities. This massive capital injection is aimed at transforming Bosch from a traditional hardware powerhouse into a world-leading AIoT, or Artificial Intelligence of Things, company, where software-defined systems and autonomous intelligence drive efficiency, quality, and new revenue streams. The investment is concentrated on embedding AI across all four of its business sectors—Mobility, Industrial Technology, Consumer Goods, and Energy and Building Technology—but its most revolutionary impact is set to unfold on the factory floor.[1][2][3]

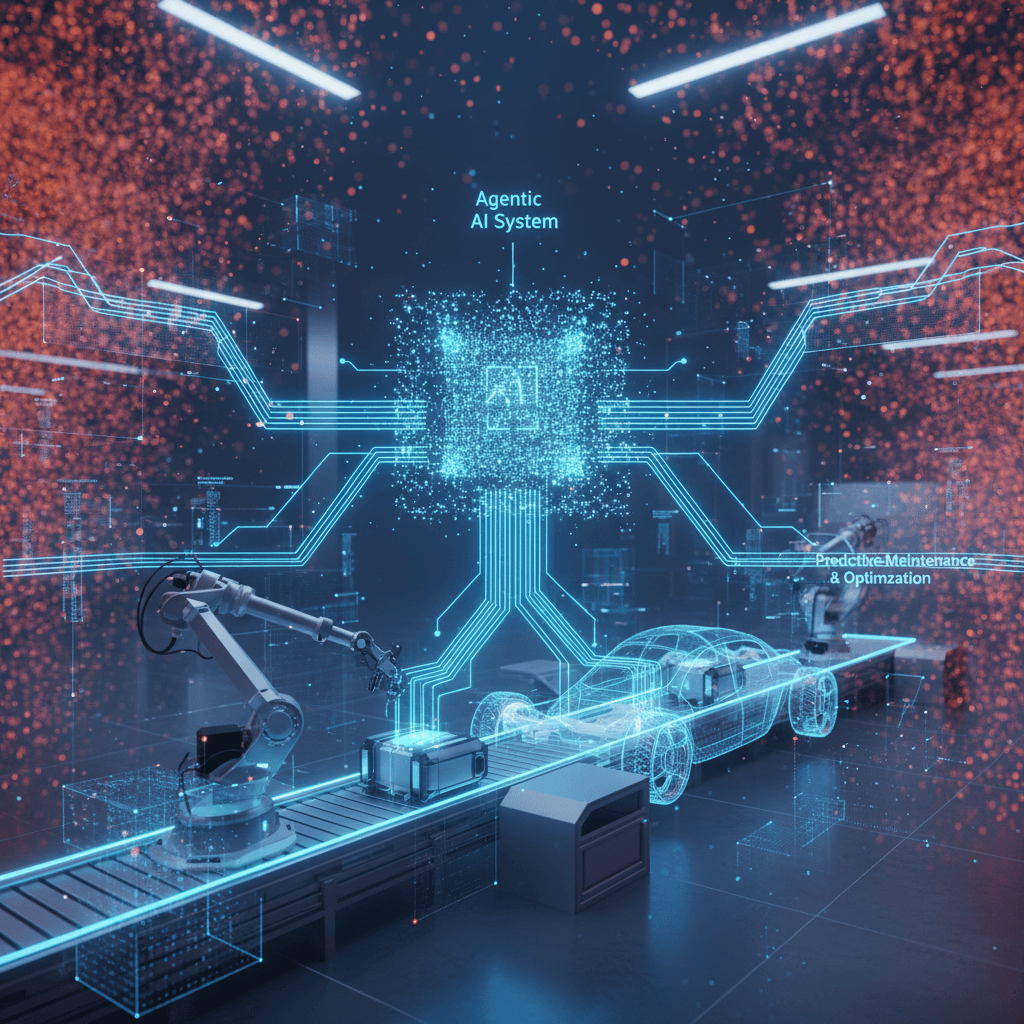

The crux of the manufacturing challenge lies in the sheer volume of real-time operational data that factories produce, an issue the initial information alludes to. In Bosch's own high-tech facilities, like its Dresden wafer fab, connected systems, sensors, and products generate a constant stream of information equivalent to 500 pages of text every single second.[4] Traditional data analysis methods are overwhelmed by this influx, leading to delays in decision-making and preventing a proactive response to emerging problems, resulting in unplanned downtime and reduced productivity. Bosch’s strategy to overcome this bottleneck centers on the widespread deployment of a revolutionary technology known as Agentic AI. This advanced form of artificial intelligence is designed not just to analyze data, but to interpret massive datasets, make largely autonomous decisions, and execute tasks without human intervention, effectively creating a 'team of AI agents' on the shop floor.[5][2] These multi-agent systems are already being utilized internally to monitor equipment, predict maintenance requirements before a machine can fail, and even optimize workforce planning, contributing to a measurable reduction in unplanned downtime. By integrating these systems, Bosch is aiming to create what it calls the "Factory of the Future," characterized by unprecedented levels of efficiency, flexibility, and cost control, a necessary evolution to compete globally, especially given comparatively high operating costs in Germany.[6][2][7]

The shifting priorities extend far beyond fixed factory assets, encompassing the company's crucial Mobility sector, which accounts for the largest share of its sales. The investment is powering the next generation of AI-based driver-assist and automated driving technologies, an area where Bosch is targeting sales of well over €10 billion by the mid-2030s.[3] AI systems are being developed to enhance vehicle environment perception and route planning, utilizing a unique internal database of vehicle sensor data to train complex generative AI models. This not only shortens the development time for new products but also increases the safety and reliability of the systems.[6] A significant part of this effort is seen in strategic collaborations, such as the memorandum of understanding with Microsoft to explore optimization of production using Agentic AI, and a partnership with self-driving truck company Kodiak AI to develop platforms for driverless trucks, supplying specialized hardware and software systems.[5][8] The push for AI is an acknowledgement that the automotive industry is rapidly transitioning to an era defined by software and intelligence embedded into traditional hardware. The goal is to maximize productivity gains and reduce costs across the entire value chain, a move that comes against a backdrop of competitive strain and recent workforce reductions that saw the company announce 13,000 job cuts by the end of 2030.[5][8]

The financial and competitive implications of this investment resonate throughout the industrial technology landscape. The company projects that sales of its AI-based software, sensor technology, high-performance computers, and network components will more than double by the mid-2030s, and expects AI-based software and services alone to generate sales of over €6 billion by the beginning of the next decade.[5][3] This revenue focus positions Bosch as a significant player in the industrial AI-as-a-service market, a strategy underlined by its plan to externalize its proprietary AI expertise. By late 2025, Bosch intends to launch a new platform that will allow other companies to create their own multi-agent AI systems, even with limited programming knowledge.[6][2] This move is set to democratize the power of Agentic AI, making advanced manufacturing optimization accessible to a wider industrial base and establishing a powerful new revenue channel for Bosch. Furthermore, the commitment highlights the company's internal focus on talent development, with its AI Academy having already trained over 65,000 employees since 2019, underscoring the necessity of a highly skilled workforce to support this AI-driven transformation.[2]

Bosch’s massive €2.9 billion investment is more than a budget line item; it is an industrial manifesto that underscores the competitive imperative of artificial intelligence in the modern global economy. It is a calculated wager that the future of manufacturing and mobility will be defined by the ability to process overwhelming data into instant, autonomous, and accurate decisions. The pivot toward Agentic AI, the aggressive sales targets in the software domain, and the push to make its AI expertise an external product all cement Bosch’s long-term vision: to be a leader in the AIoT space. By embedding intelligence into every product and process, from the automated quality inspection systems using deep learning in its factories to the advanced driver-assist systems in its mobility solutions, the company is attempting to prove that a society and a corporation without robust AI capabilities will inevitably fall behind in global competition.[6][9] This profound shift suggests that for industrial titans, the road to future growth is paved not with physical components alone, but with software and the self-learning, autonomous intelligence that can harness the tidal wave of data.