AI Revolutionizes Mining: Unearthing Gains in Safety, Efficiency, Sustainability

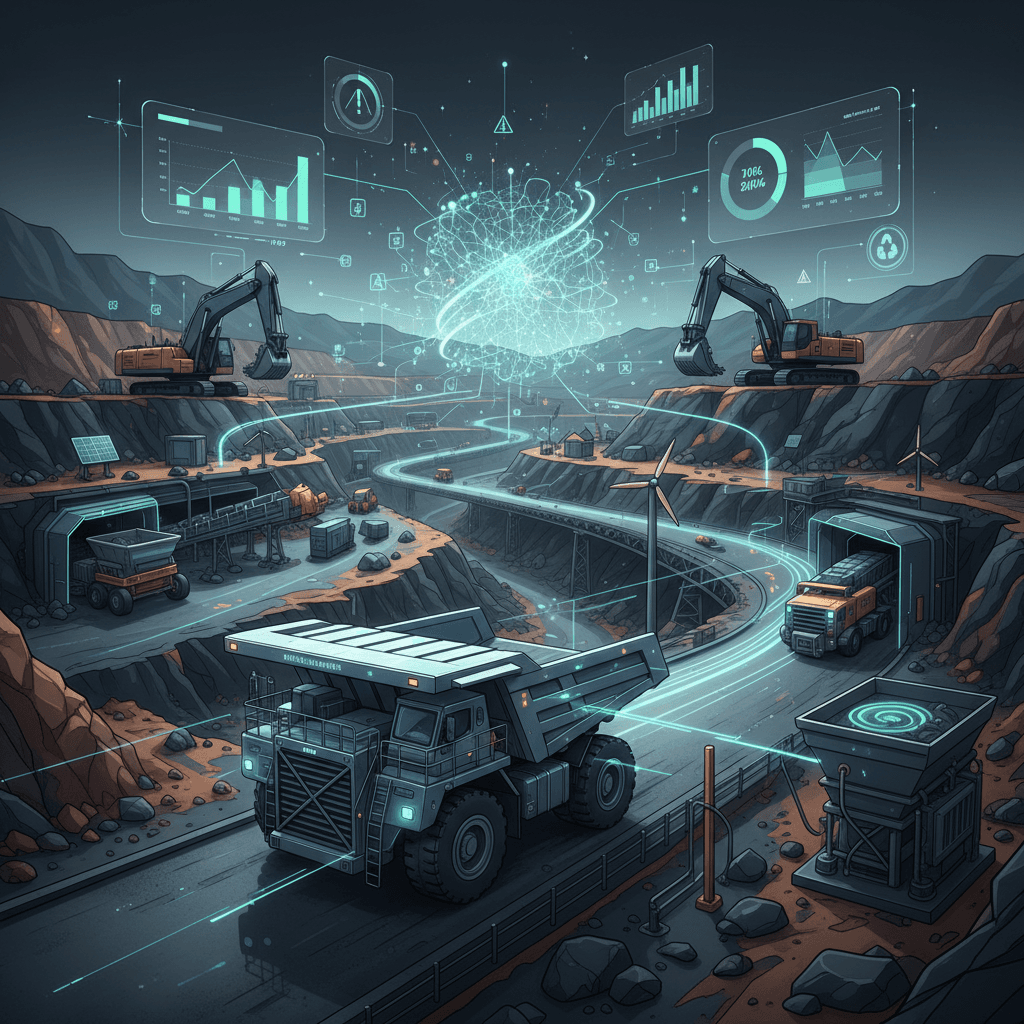

Unearthing value: Mining pioneers a problem-driven AI approach for safety, efficiency, and sustainability, guiding other industries.

December 16, 2025

The heavy-duty world of mining, an industry traditionally reliant on machinery and manual labor, is unearthing significant value from the depths of its own data through the strategic deployment of artificial intelligence. Major players in the sector are demonstrating how AI can be a powerful tool for enhancing efficiency, safety, and environmental sustainability, offering a blueprint for other industrial sectors to follow. Mining conglomerate BHP, for instance, is framing AI as the key to transforming its vast streams of operational data into smarter, more effective day-to-day decisions.[1][2] By analyzing information from a myriad of sensors and monitoring systems, the company is able to identify patterns and preemptively flag potential issues with plant machinery. This provides decision-makers with the insights needed to optimize processes, improve safety protocols, and lessen the environmental impact of their operations.[1]

A crucial lesson emerging from the mining industry's foray into AI is the importance of a problem-driven approach over a technology-first mindset. For business leaders at BHP, the pivotal question was not "Where can we use AI?" but rather "Which decisions do we make repeatedly, and what information would improve them?".[1] This philosophy has led to a portfolio of AI applications that target specific, high-impact business challenges, moving beyond isolated pilot projects to treating AI as a core operational capability.[1] The company initiated its AI journey by focusing on a select group of problems that were hampering performance, where the impact of AI-driven changes could be quantifiably measured.[1] Each of these use cases was assigned a dedicated owner and a corresponding key performance indicator (KPI), with results being reviewed with the same rigor as other operational metrics. This strategic focus on solving tangible problems has been instrumental in demonstrating the return on investment of AI, a significant concern for many organizations considering similar technological shifts. Reports indicate that 38 percent of companies find it difficult to project a specific ROI for industrial AI, and another 26 percent are challenged by the implementation costs themselves.[3]

The practical applications of AI in mining are both varied and impactful, extending across the entire value chain from mineral extraction to customer delivery.[1][2] Predictive maintenance has emerged as a particularly successful use case. By employing AI models to analyze data from sensors on heavy equipment, companies can anticipate maintenance needs and schedule repairs during planned downtime, thereby reducing unexpected and costly failures.[1][4] This proactive approach not only cuts down on the number of breakdowns but also mitigates the safety risks associated with equipment malfunctions.[1] For example, Brazilian mining giant Vale has utilized predictive analytics to extend the lifespan of its haul trucks by 30% and predict up to 85% of rail breakdowns in advance, saving an estimated $7 million annually.[4] Similarly, autonomous vehicles and machinery are becoming increasingly common, with AI-powered systems enabling equipment to operate in hazardous environments without human intervention, improving safety and productivity.[5] At the Spence mine in Chile and in its Western Australian Iron Ore operations, BHP's autonomous haul trucks have reduced costs by approximately 20% while eliminating human risk.[6]

Beyond operational efficiency and safety, AI is also playing a critical role in advancing the mining industry's sustainability goals. In an era of increasing environmental scrutiny, AI helps companies meet these demands by optimizing the use of resources like water and energy.[1] At BHP's Escondida copper mine in Chile, the implementation of AI technology has resulted in savings of over three billion liters of water and 118 gigawatt-hours of energy since fiscal year 2022.[6][2][7] This was achieved through real-time data analytics that optimize water recycling in desalination plants and energy consumption in concentrators.[6] Furthermore, AI is being used to enhance mineral exploration by analyzing vast geological datasets to more accurately predict the location of mineral deposits, which reduces the need for unnecessary and disruptive drilling and excavation.[2][8] This precision not only minimizes the environmental footprint but also improves the economic viability of exploration efforts.

The journey of integrating AI in the mining sector is not without its challenges, many of which are common to other heavy industries. The need for large volumes of high-quality data is paramount, as the performance of AI models is heavily dependent on the data they are trained on.[9] Inaccurate or incomplete data can lead to unreliable results.[9] There is also the complexity and cost associated with developing and implementing AI systems, which can be a significant hurdle for many organizations.[9] Furthermore, a culture of traditional industrial engineering can sometimes lead to resistance to change and skepticism towards new technologies.[9][10] Overcoming these challenges requires a strategic approach that includes investing in data infrastructure, starting with smaller, manageable projects to demonstrate value, and fostering a company culture that embraces innovation and data-driven decision-making.

In conclusion, the mining industry's adoption of AI offers a rich seam of learnings for other sectors embarking on their own AI transformations. By focusing on solving specific, high-value business problems, meticulously measuring the impact of AI initiatives, and strategically scaling successful applications, companies can navigate the complexities of AI deployment. The successes in predictive maintenance, autonomous operations, and resource optimization within mining provide a compelling case for the transformative potential of AI in even the most traditional of industries. As businesses across all sectors grapple with how to best leverage artificial intelligence, the lessons being unearthed in the world of mining provide a clear and valuable guide for turning data into tangible, real-world value.