Agnikul Cosmos pioneers fully reusable rockets, slashing small satellite launch costs.

Indian startup Agnikul targets drastic cost cuts and sustainable space access with pioneering fully reusable launch vehicles.

September 29, 2025

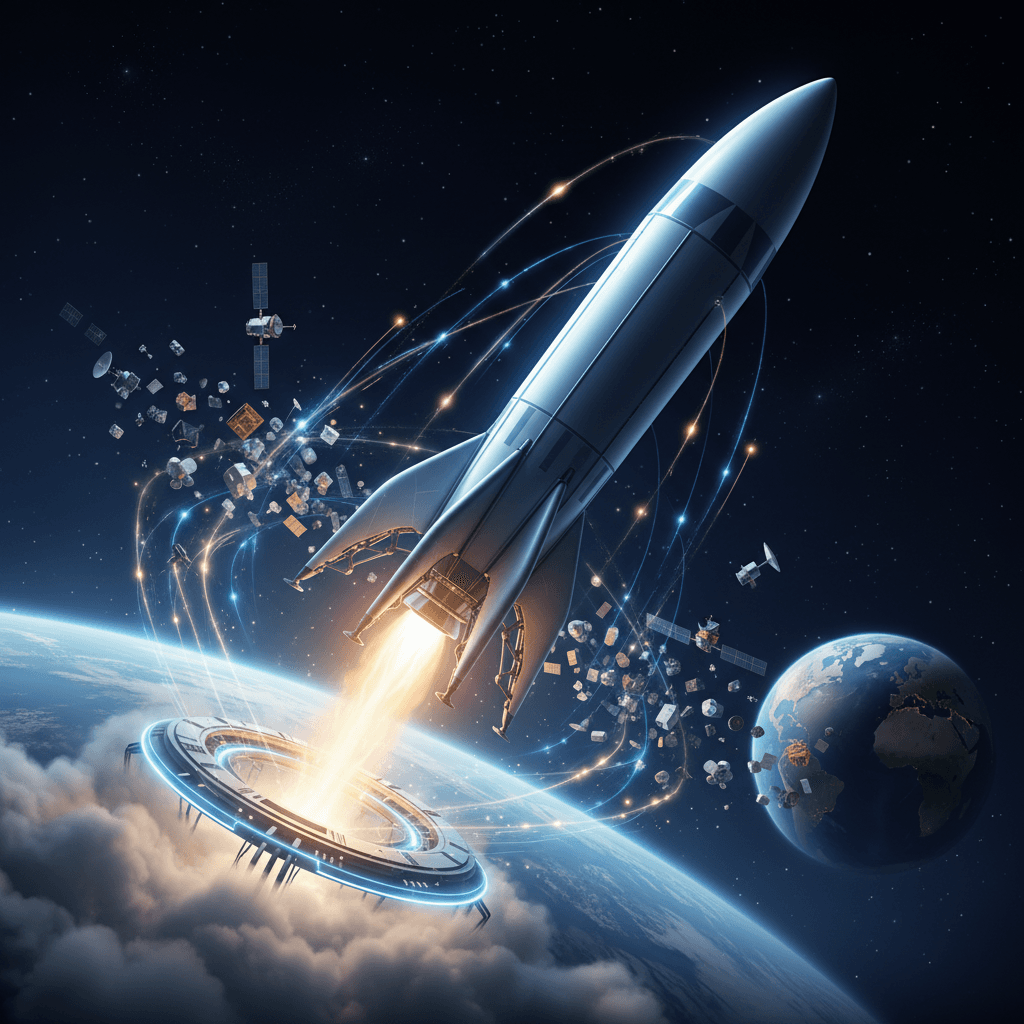

In a significant move poised to reshape the commercial spaceflight landscape, Chennai-based startup Agnikul Cosmos has announced an ambitious roadmap to develop fully reusable rockets. The declaration, made at the International Astronautical Congress in Sydney, outlines a vision where no part of the launch vehicle is expended or left behind as orbital debris.[1][2][3][4][5] This commitment to complete reusability aims to drastically lower the cost of launching small satellites, positioning the Indian startup as a contender in the globally competitive market. Agnikul's strategy is built upon a foundation of proprietary technology, including numerous patents secured in the United States, Europe, and India, and follows the successful test flight of its first launch vehicle.[1][6][3] The company's goal is to make space access more affordable, flexible, and sustainable, directly challenging the traditional expendable rocket model.

The core of Agnikul's ambitious plan is to achieve full booster recovery after launch and to extend the operational life of the rocket's upper stage in space.[6] This approach mirrors the industry-disrupting success of SpaceX's Falcon 9 but is tailored for the small satellite market.[6] Central to this strategy is the company's patented technology for a combined launch vehicle and satellite system, coupled with the use of semi-cryogenic propellants.[1][7][3] This specific propellant choice is designed to enable more efficient refurbishment and support cost-effective re-flights, which are critical for a commercially viable reusable system.[1][7] Co-founder and CEO Srinath Ravichandran has emphasized that affordability and flexibility have been core design principles from the project's inception.[1][6][7] The pursuit of reusability is seen not as an add-on, but as a fundamental requirement for the commercial viability of small satellite launchers, a point stressed by Co-founder and COO Moin SPM.[3] This long-term vision is backed by a series of technological patents covering multi-purpose and recovery technologies that form the legal and innovative backbone of their reusability push.[1][6][3]

This bold new direction is built upon a series of significant technological milestones, most notably the successful launch of the Agnibaan Sub-Orbital Technology Demonstrator (SOrTeD).[8][9] This mission, which served as a crucial test flight, validated many of the homegrown technologies essential for orbital flights.[9][10] The SOrTeD mission was a landmark event for India's private space industry, marking the first-ever launch from a private launchpad and the first controlled flight of a semi-cryogenic liquid engine produced through additive manufacturing.[8][11][9][10] The flight successfully demonstrated the functionality of Agnikul's proprietary autopilot algorithms, in-house designed avionics, and engine control systems.[1][3] The rocket was powered by the Agnilet engine, a single-piece, 3D-printed, semi-cryogenic engine entirely designed and built in-house, a feat that itself is a world-first.[8][9] The successful test provided crucial flight data and confirmed that the company's core systems could work in concert, paving the way for the development of the full-scale, reusable Agnibaan orbital vehicle.[9][10]

Underpinning Agnikul's rapid innovation and its reusability goals is a deep investment in advanced manufacturing. The company has strategically vertically integrated its production by establishing India's first private large-format additive manufacturing (LFAM) facility dedicated to aerospace systems in Chennai.[12][13] This facility combines design, printing, post-processing, and testing under one roof, dramatically shortening development cycles from months to days.[12][13] Agnikul asserts that this 3D-printing-centric approach can reduce rocket production costs by as much as 50%.[3][5] The facility is capable of printing large components up to a meter in height, including single-piece rocket engines that are significantly more powerful than their earlier prototypes.[12][14][15][13] By eliminating complex assembly involving welds, joints, and fasteners, the single-piece engines are not only faster and cheaper to produce but also inherently more reliable.[12] This in-house manufacturing capability is a key enabler of the company's plan, allowing for quick iteration and scaling of production to meet the demands of a commercially focused launch service.[7][13]

The journey of Agnikul is emblematic of the broader transformation within India's space industry, which is increasingly opening up to private participation. The startup's progress has been significantly bolstered by critical support from the Indian Space Research Organisation (ISRO) and the nation's space regulator, IN-SPACe.[6][7] This government backing has provided Agnikul with access to essential facilities and technical expertise, and, crucially, has created a policy environment friendly to exploring complex technologies like rocket stage recovery and reuse.[6][7] Founded in 2017 within IIT Madras, the company has successfully raised significant capital, with its total funding exceeding $60 million from a mix of domestic and international investors.[16][17][18] This financial backing, combined with regulatory support and its own technological prowess, has allowed Agnikul to become a leading player in India's burgeoning private space ecosystem.[5][15]

In conclusion, Agnikul Cosmos's announcement to pursue fully reusable rockets marks a pivotal moment for the company and for India's space ambitions. By leveraging its proven success in 3D-printed propulsion and advanced avionics, the startup is not merely entering the launch market but is aiming to redefine its economics. The successful realization of a fully reusable launch vehicle would significantly reduce costs for small satellite operators, increase launch frequency, and promote a more sustainable use of space by mitigating the creation of orbital debris.[3] This endeavor, a testament to homegrown Indian innovation, has the potential to solidify the nation's standing in the global space economy and usher in a new era of more accessible and responsible spaceflight.[7][3]

Sources

[4]

[9]

[10]

[13]

[17]

[18]